- Reduced Tooling Cost. The dip brazing process uses little if any specialized tooling. Fixturing is generally accomplished with common fixtures that allow for quick and inexpensive configuration changes.

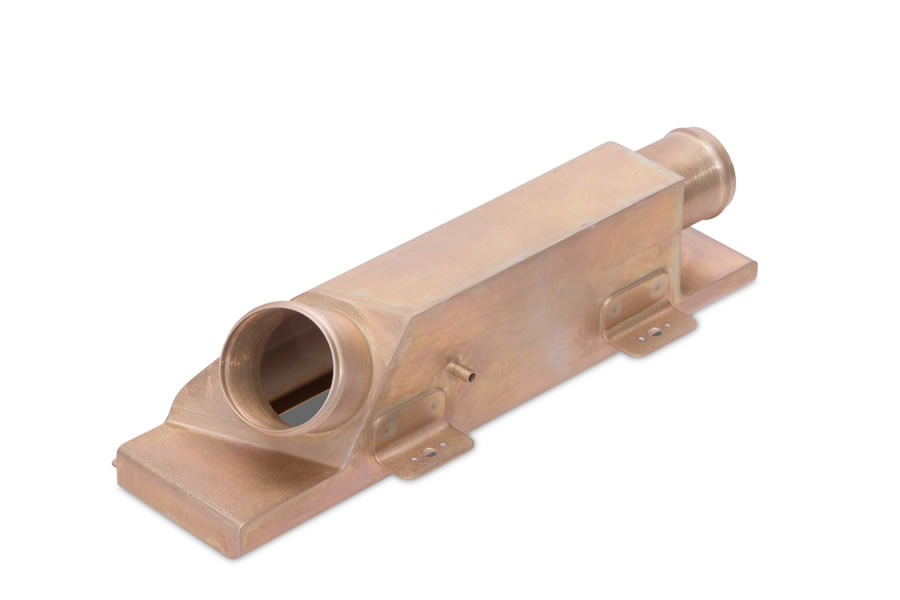

- Material Savings. Unlike castings or machined parts, dip brazing can be done at near net size.

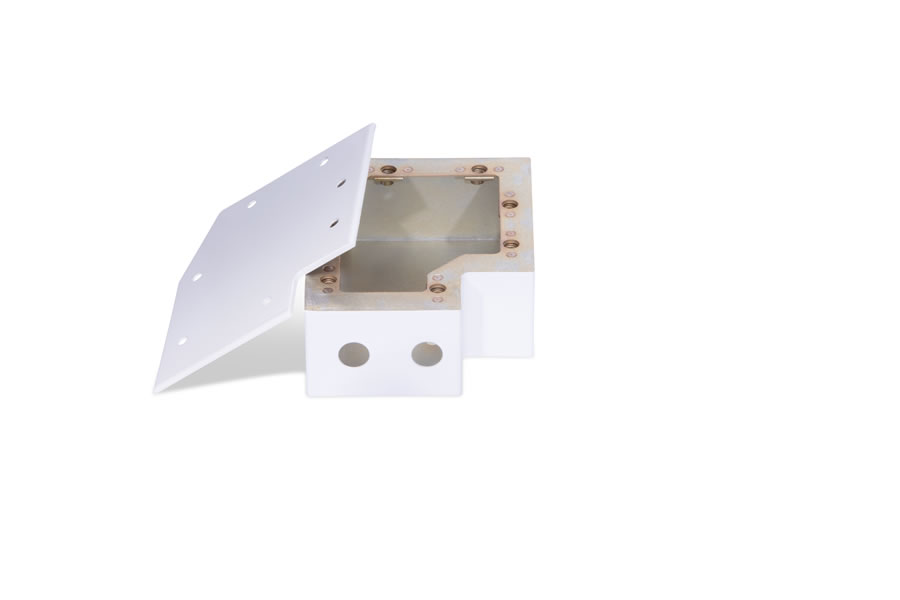

- Improved Structural Integrity. Dip brazing offers a continuous leak-tight and EMI shielded joint even with a variety of material thicknesses.

- Better Conductivity. As the dip brazed joint is aluminum, conductivity is clearly better than that achieved with an adhesive bonded or mechanically attached assembly.

- Less Distortion. The braze process heats all components uniformly thus yielding distortion less than that of a welded part.

- Lower Cost. The dip brazed process yields the lowest cost given the superior characteristics achieved.

- Design Freedom. The design engineer will enjoy a greater range of options using the dip brazed process.

- Reduced Tooling Costs

- Reduced Design Change Cost and Implementation Time