OVERVIEW

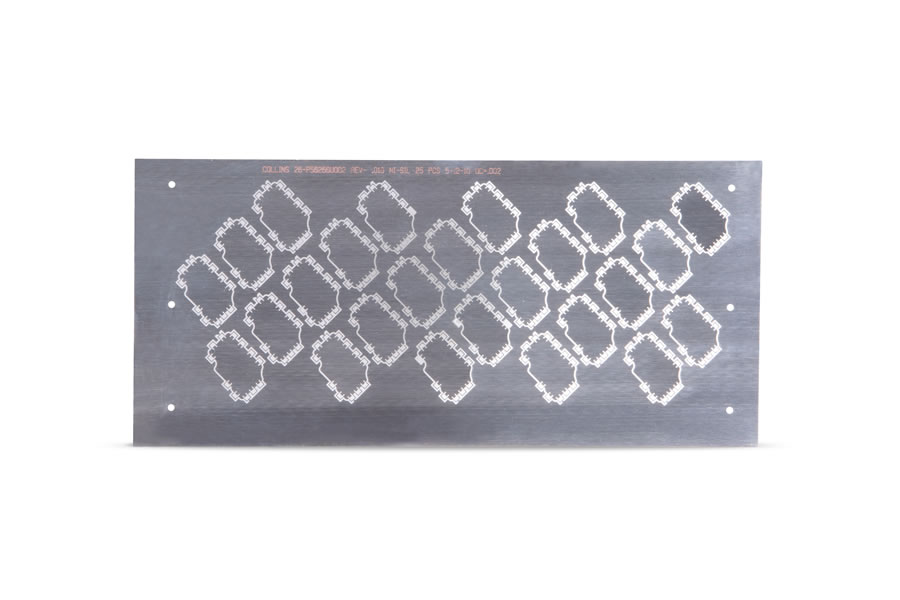

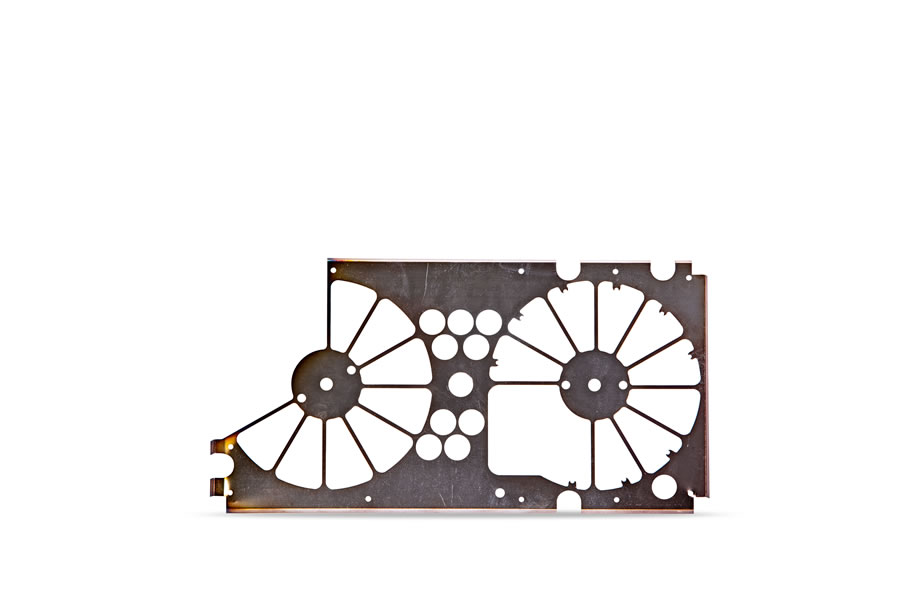

The photo chemical etching process is used to produce very precise parts that would otherwise be difficult or impossible to manufacture using conventional fabrication methods. This technology was first commercially used during World War Two for producing gun sight reticles.

A brief outline of possibilities and limitations follows. This information is presented to provide the reader with rough guidelines rather than the maximum limits achievable by chem-etch.

PHOTO-CHEMICAL ETCHING PROCESS

- Generate artwork on mylar from Mech-Tronics CAD system or customer supplied data.

- Clean and pre-treat the material.

- Apply 1.5 mil dry PHOTO RESIST (photographically resistant) mylar layered film to the metal sheet to be etched.

- Expose the film via UV (Ultraviolet) light to transfer the piece part photographically to the previously treated sheet of metal.

- Expose the part image on the film and then develop the image on the metal sheet to fix it in place.

- Chemically remove the unprotected material areas by etching with the proper acid for the material within an enclosed chamber.

- Rinse and strip the photographically resistant film from the sheet.

- Proceed to next steps of manufacturing operations, forming, dip brazing, hardware insertion, silk screening, finishing, etc.